for Fresh, ESL and Shelf-Stable Liquids

Cost-efficient and user-friendly filling equipment for Bag-in-Box liquid applications. Equipment is also suitable for filling bags for drums, bins, IBC and other containers.

Applications

Wine, water, dairy, condiments, post-mix syrups, liquid egg, edible oil and chemicals, among other liquids.

Benefits of Autokap™ filling machines:

- Easy operator interface

- Suitable for both hot and cold filling

- Flexible speed ranging from 5 to 18 bags per minute

- Compatible with a large range of fitments, caps and dispensers

- Quick and simple bag size changes (up to 10L - without mechanical adjustment)

- Cleaned in place/steamed in place features (CIP/SIP)

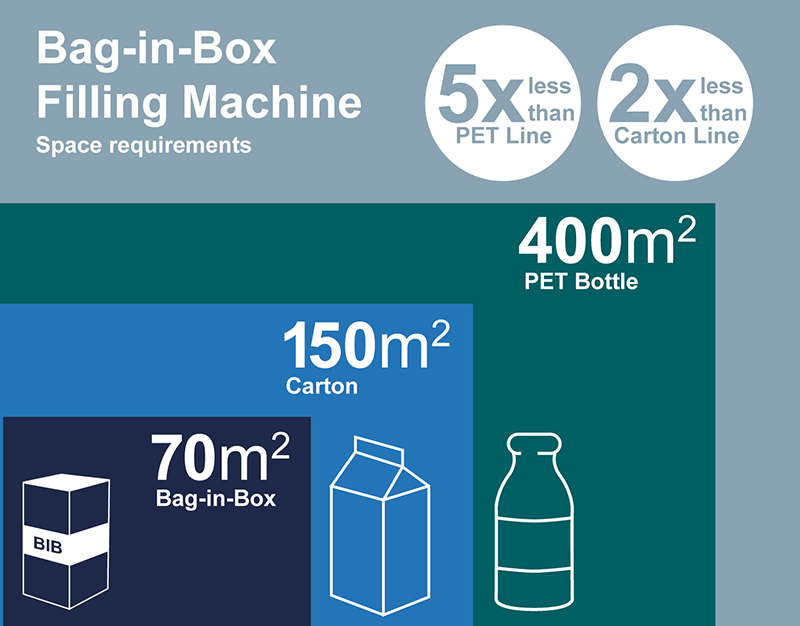

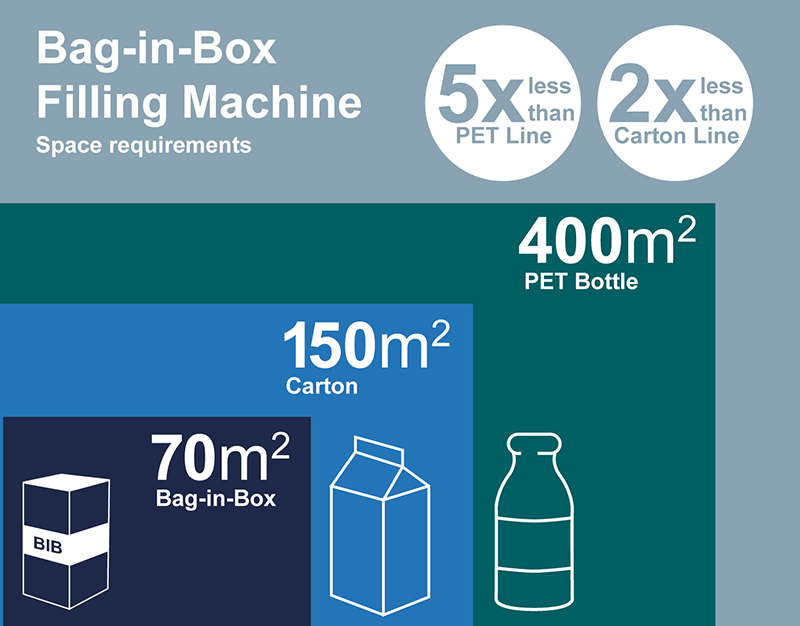

- Compact size

Rapak fillers have been designed to USA 3A, FDA and European Hygienic Engineering & Design Group (EHEDG) standards and comply with EU Health and Safety work acts. Noise level is under 80 decibels.

View our range of Autokap Filling Machines:

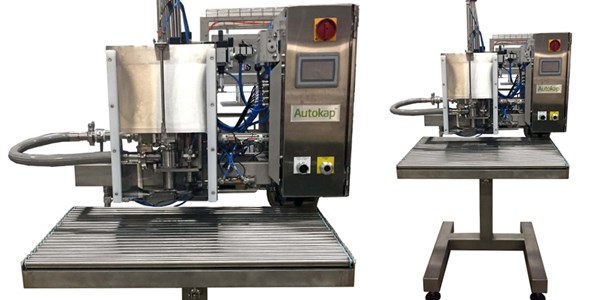

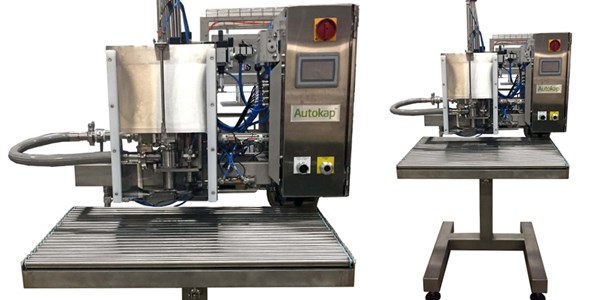

Autokap™ 600 Single-Head Semi-Automatic Filling Machine

This filler is designed to fill 1.5 - 20 L (0.5 - 5 gal.) bags at a lower production output. Bags are manually loaded into the filler and after filling, they are released to a table or onto the roller conveyor to be inserted into the box.

Production output*

- 5L (0.5 gal.) bags at up to 9 bags/min

- 3L (1 gal.) at up to 8 bags/min

- 5L (1.5 gal.) bags at up 7 bags/min

- 10L (2.5 gal.) bags at up to 6 bags/min

- 20L (5 gal.) bags at up to 5 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 900 Twin-Head Semi-Automatic Filling Machine

This filler is designed to fill 1.5 - 20 L (0.5 - 5 gal.) bags . Bags are manually loaded into the filler and after filling, they are released to a table or onto the roller conveyor to be inserted into the box.

Production output*

- 5L (0.5 gal.) bags at up to 11bags/min

- 3L (1 gal.) bags at up to 10 bags/min

- 5L (1.5 gal.) bags at up 9 bags/min

- 10L (2.5 gal.) bags at up to 8 bags/min

- 20L (5 gal.) bags at up to 7 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1200 Single-Head Fully-Automatic Filling Machine

This high-speed filler is designed to fill 1.5 - 20 L (0.5 - 5 gal.) bags. It can be integrated to the production line with automatic carton erection and sealing, check weighers and palletizers. It is servo driven for better accuracy.

Production output*

- 5L (0.5 gal.) bags at up to 17 bags/min

- 3L (1 gal.) bags at up to 16 bags/min

- 5L (1.5 gal.) bags at up to 14 bags/min

- 10L (2.5 gal.) bags at up 11 bags/min

- 20L (5 gal.) bags at up to 9 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1400 Single-Head Fully-Automatic Filling Machine

This high-speed filler is designed to fill and automatically load 1.5 - 20 L (0.5 - 5 gal.) bags into boxes. It can be fully integrated to the production line with automatic carton erection and sealing, check weighers and palletizers. It is pneumatic driven. Bags are fed into the machine spout trailing.

Production output*

- 5L (0.5 gal.) bags at up to 19 bags/min

- 3L (1 gal.) at up to 18 bags/min

- 5L (1.5 gal.) bags at up 15 bags/min

- 10L (2.5 gal.) bags at up to 11 bags/min

- 20L (5 gal.) bags at up to 8 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1700 Single-head, Fully Automatic Filling Machine

This high-speed filler is designed to fill and automatically load 1.5 - 20 L (0.5 - 5 gal.) bags into boxes. The 1700 incorporates features of Rapak’s two most popular filling machines - the Autokap 1200 and 1400 series:

- Fixed fill head - keeps the bag stationary during the filling process, reducing product splash and strain on the bag spout seal

- Accepts bags spout leading with a servo drive bag infeed system, allowing for precise bag positioning

Production output*

- 5L (0.5 gal.) bags at up to 19 bags/min

- 3L (1 gal.) at up to 18 bags/min

- 5L (1.5 gal.) bags at up 16 bags/min

- 10L (2.5 gal.) bags at up to 13 bags/min

- 20L (5 gal.) bags at up to 11 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1900 Single-head Semi-automatic Bulk Filling Machine

This filler is designed to fill drums or bulk containers ranging from 30G up to 1000L. It is equipped with a Micro Motion mass flowmeter that ensures precise fill weights during the fill process. The 1900 is ideal for filling hot and ambient temperature viscous products such as pulpy juice, sauces or purees with particulate as large as 5/8” in size.

Production output*

- 200L bags at up to 18 bags/hr

- 1000L bags at up to 4 bags/hr

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.