Hygienic, user-friendly and more sustainable packaging solution for Retail, Foodservice and Industrial use

Why is Bag-in-Box a better option for Edible Oil?

Compared to plastic or glass bottles or metal containers:

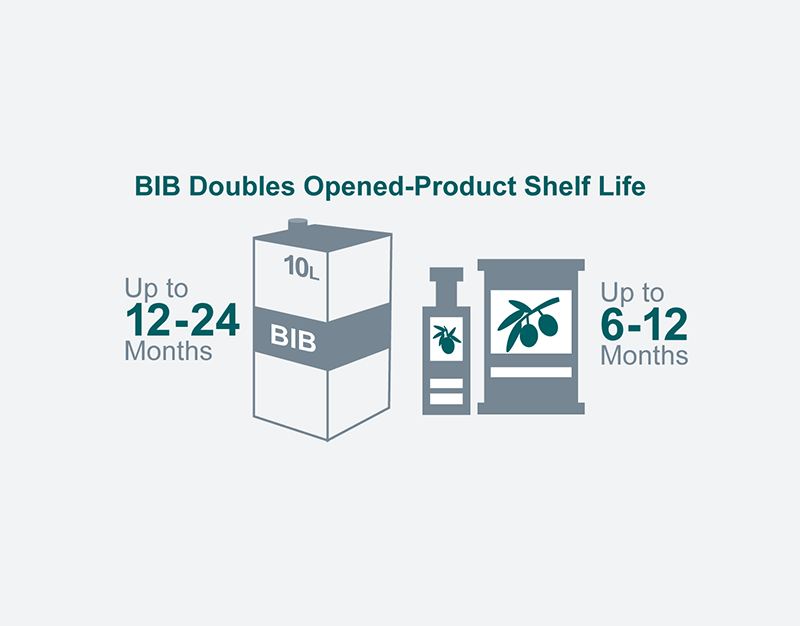

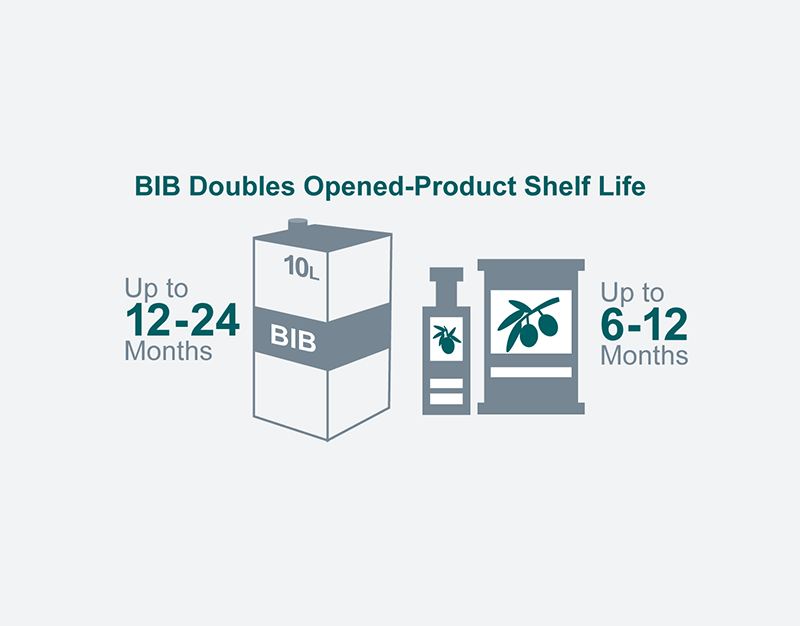

Product preservation

Minimal contact with air ensures:

- Extended product shelf life after first opening

- Reduced contamination risk

- Provides UV- light protection

Storage & Logistics

- 80% less space when empty (foldable)

- 45% less space when full (stackable)

- 49 times lighter than steel

Handling

- Hygienic filling, transfer and dispensing

- User-friendly pouring

- Easy bulk shipping and dispensing options

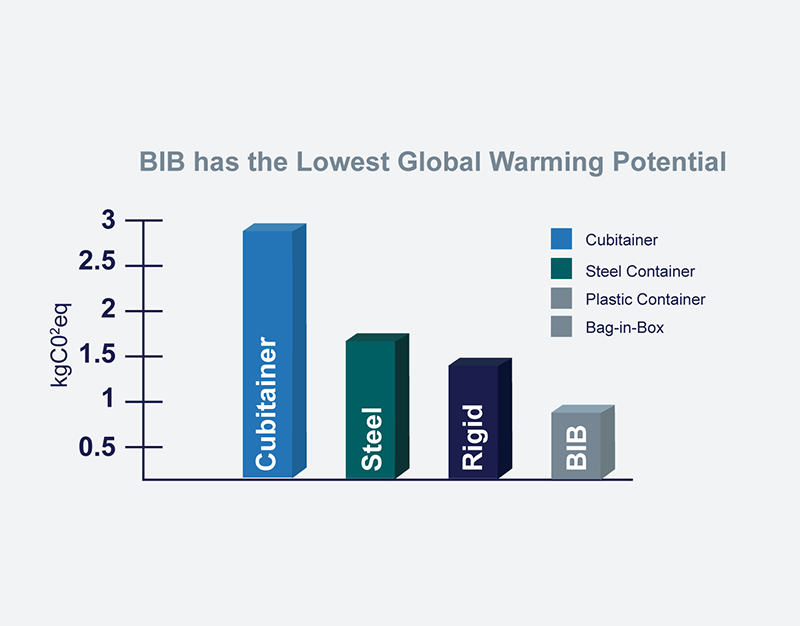

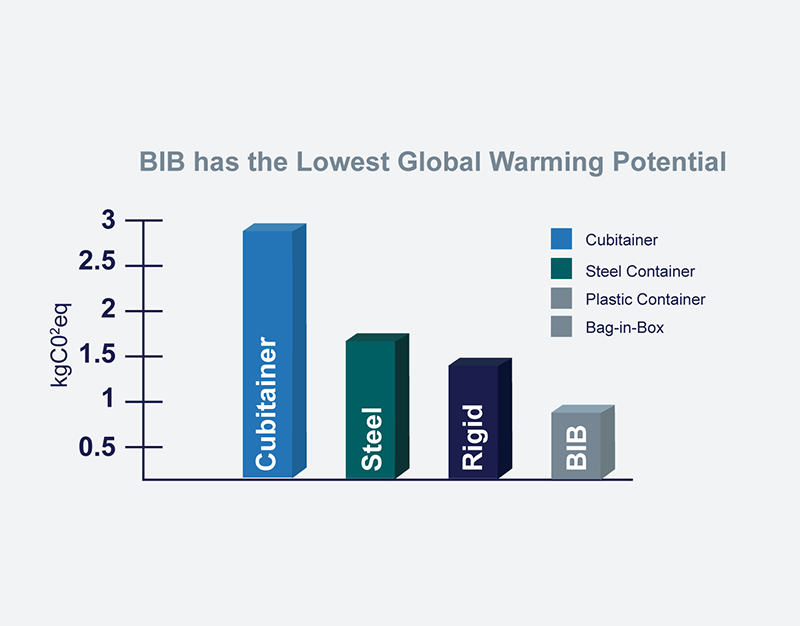

Environmental

- 40-44% lower carbon footprint vs plastic/steel

- 5 times less waste

- 100% recyclable box

Financial

- Very low investment cost

- Total Cost of Ownership savings

Bags & Films for Edible Oil

Rapak offers a wide range of film options including LLDPE + PE, EVOH with PE and METPET + PE. Our specially designed bags for edible oil provide excellent moisture barrier and grease resistance. Sizes rang from 0.75L to 1400L (0.5G. to 370G.). Common sizes for food service are 10/ 20L. and 32-35 lbs. or 5G. with custom sizing available.

All our products are EU and FDA approved for direct food contact and free from phthalates, heavy metals and Bisphenol A.

Taps, Fitments & Connectors for Edible Oil

Rapak’s fitment range for edible oil Bag-in-Box includes dispensing taps, pouring caps, and line-side connectors. Our offerings provide controlled pouring that is convenient for at home use as well as the quick service, movie theater and food service industries.

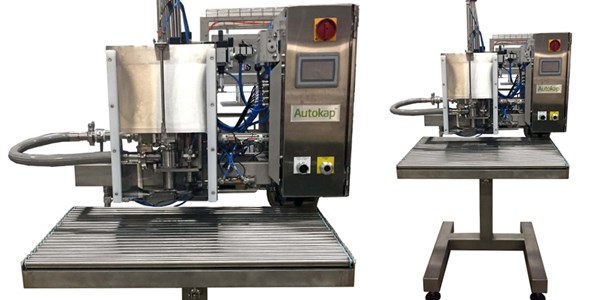

Filling Machines for Edible Oil

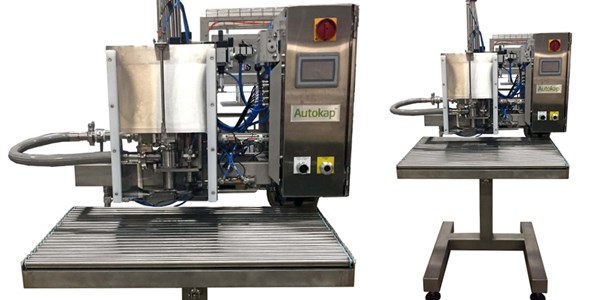

Autokap™ 600 Single-Head Semi-Automatic Filling Machine

This filler is designed to fill 1.5 - 20 L (0.5 - 5 gal.) bags at a lower production output. Bags are manually loaded into the filler and after filling, they are released to a table or onto the roller conveyor to be inserted into the box.

Production output*

- 5L (0.5 gal.) bags at up to 9 bags/min

- 3L (1 gal.) at up to 8 bags/min

- 5L (1.5 gal.) bags at up 7 bags/min

- 10L (2.5 gal.) bags at up to 6 bags/min

- 20L (5 gal.) bags at up to 5 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 900 Twin-Head Semi-Automatic Filling Machine

This filler is designed to fill 1.5 - 20 L (0.5 - 5 gal.) bags . Bags are manually loaded into the filler and after filling, they are released to a table or onto the roller conveyor to be inserted into the box.

Production output*

- 5L (0.5 gal.) bags at up to 11bags/min

- 3L (1 gal.) bags at up to 10 bags/min

- 5L (1.5 gal.) bags at up 9 bags/min

- 10L (2.5 gal.) bags at up to 8 bags/min

- 20L (5 gal.) bags at up to 7 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1200 Single-Head Fully-Automatic Filling Machine

This high-speed filler is designed to fill 1.5 - 20 L (0.5 - 5 gal.) bags. It can be integrated to the production line with automatic carton erection and sealing, check weighers and palletizers. It is servo driven for better accuracy.

Production output*

- 5L (0.5 gal.) bags at up to 17 bags/min

- 3L (1 gal.) bags at up to 16 bags/min

- 5L (1.5 gal.) bags at up to 14 bags/min

- 10L (2.5 gal.) bags at up 11 bags/min

- 20L (5 gal.) bags at up to 9 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1400 Single-Head Fully-Automatic Filling Machine

This high-speed filler is designed to fill and automatically load 1.5 - 20 L (0.5 - 5 gal.) bags into boxes. It can be fully integrated to the production line with automatic carton erection and sealing, check weighers and palletizers. It is pneumatic driven. Bags are fed into the machine spout trailing.

Production output*

- 5L (0.5 gal.) bags at up to 19 bags/min

- 3L (1 gal.) at up to 18 bags/min

- 5L (1.5 gal.) bags at up 15 bags/min

- 10L (2.5 gal.) bags at up to 11 bags/min

- 20L (5 gal.) bags at up to 8 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1700 Single-head, Fully Automatic Filling Machine

This high-speed filler is designed to fill and automatically load 1.5 - 20 L (0.5 - 5 gal.) bags into boxes. The 1700 incorporates features of Rapak’s two most popular filling machines - the Autokap 1200 and 1400 series:

- Fixed fill head - keeps the bag stationary during the filling process, reducing product splash and strain on the bag spout seal

- Accepts bags spout leading with a servo drive bag infeed system, allowing for precise bag positioning

Production output*

- 5L (0.5 gal.) bags at up to 19 bags/min

- 3L (1 gal.) at up to 18 bags/min

- 5L (1.5 gal.) bags at up 16 bags/min

- 10L (2.5 gal.) bags at up to 13 bags/min

- 20L (5 gal.) bags at up to 11 bags/min

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Autokap™ 1900 Single-head Semi-automatic Bulk Filling Machine

This filler is designed to fill drums or bulk containers ranging from 30G up to 1000L. It is equipped with a Micro Motion mass flowmeter that ensures precise fill weights during the fill process. The 1900 is ideal for filling hot and ambient temperature viscous products such as pulpy juice, sauces or purees with particulate as large as 5/8” in size.

Production output*

- 200L bags at up to 18 bags/hr

- 1000L bags at up to 4 bags/hr

*All outputs are based on filling water at a flow rate of 6 liters/sec (90 gallons/min). Filling rate is dependent on product supply conditions.

Bag-in-Box, a more sustainable packaging option

Bag-in-Box is a more sustainable alternative to other forms of packaging, enabling carbon reductions, cost savings and efficiencies in our customers’ supply chains. Bag-in-Box has excellent environmental credentials as it is easier to transfer, store and dispose of in regular waste collections.

Rapak bag’s specialized film properties offer longer shelf-life to opened products than traditional containers.